Mechatronics machine construction

Need a specialist in mechatronics machine construction? At VDL Industrial Modules we tailor our approach to your product and required volume. Whether it concerns a few pieces to start up your production or setting up a complete production line: we have everything in-house to design and assemble the mechatronic construction.

Mechatronics machine construction for OEMs in hightech, mobility, energy, infrastructure and foodtech

We build in mechatronic modules and machines for OEMs active in Hightech, Mobility, Energy, Infratech and Foodtech. These markets have to deal with rapid developments, strict requirements and continuously changing legislation. With our years of experience and the right certifications, we have all the specialist knowledge in-house. With mechatronics machine construction by VDL Industrial Modules you are assured of the quality, safety and hygiene that the machines must meet.

Build-to-print mechatronics machine construction

With our build-to-print approach, we build the mechatronic module or machine according to the exact specifications. This makes the production process smooth and fast. In addition, we take into account our capacity to absorb an increase in volume. This makes us flexible to grow to a complete assembly line for the product.

We only invest in tools and equipment when this is cost-effective. Our technicians strive for improvements every day and continue to look for ways to assemble even more efficiently.

Check out some of our

REFERENCES

Flexible and future-proof sorting

An autonomous sorting solution designed by Prime Vision to create

a flexible and future-proof sorting center.

Future of paint mixing systems

Pearls is the first and only volumetric dosed paint mixing system of

solid colorants in the coating industry.

Sustainable alternative to fertilizer

Using water, air, electricity and plasma technology Vitalfluid produces

plasma water (PAW).

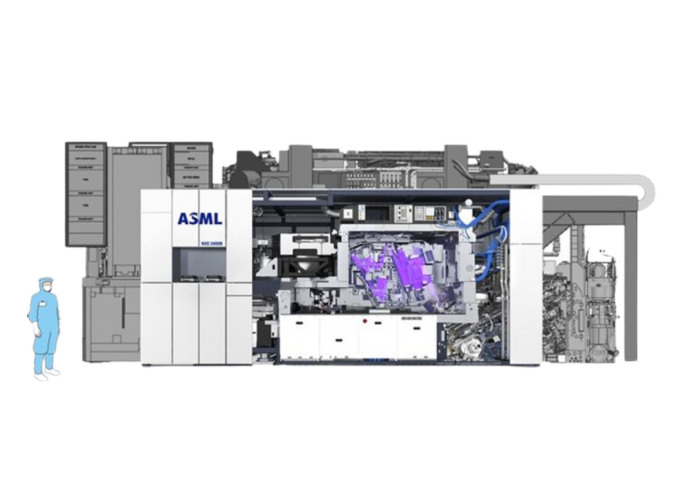

Scaling up in the semiconductor industry

ASML's lithography systems are central to the process to make

microchips.

All-round mechatronics machine construction

In addition to build-to-print, you can also contact VDL Industrial Modules for all-round mechatronics machine construction. This is a perfect match when your systems are made up of different modules or components and require flexibility in assembly. Do you also outsource the development of your module or machine to us? Then you benefit from extra speed. We build immediately what we have developed.

Quality comes first in our mechatronics machine construction

We aim for zero defects. To achieve this goal, all our procedures within the production process are designed to achieve the highest quality assurance. We check purchased parts immediately upon receipt. We also measure and register how many machines and modules meet our strict quality requirements at the end of the production process (first pass yield).

We already register 'errors' during production. By learning from this immediately, we prevent mistakes in the future and even more machines reach the finish line. After production we carry out a strict final inspection. We can also perform a Factory Acceptance Test (FAT), with which we evaluate whether the equipment has been built according to agreed specifications. We also extensively test whether all functionalities of the machine work properly. We will adjust any deviations for you before shipment.

Would you like to know more about mechanical engineering at VDL Industrial Modules?

Discover how we ensure high-quality, cost-efficient mechatronics machine construction with our optimally designed supply chain and continuous pursuit of improvements.